Parylene XY is a transparent, thin (hundreds of nanometers to a few micrometers), well adhering, pin-hole and defect free conformal coating. They are coated uniformly on flat surfaces and component configurations with sharp edges, points, flat surfaces, crevices or exposed internal surfaces are coated uniformly without voids.

Why is Parylene tough to verify?

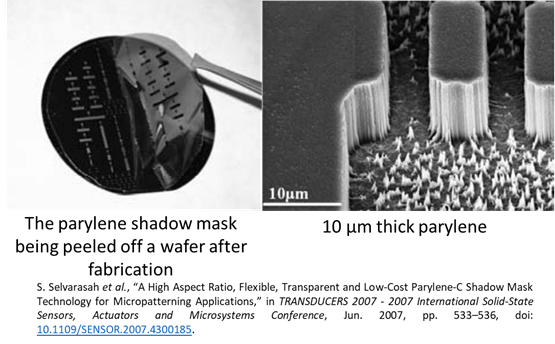

Because Parylene XY is transparent and forms a flawless / continuous layer its inspection becomes hard to the bare eye. Different types of inspection processes can be followed to verify the presence or uniformity of Parylene depending on which tools you have access to. The easiest at home inspection method is to inspect the de-masking lines. When a customer sends us a substrate for Parylene XY coating process, we receive a mask scheme along with other instructions. Masking process is necessary to protect the areas where Parylene XY must not be deposited. After the chemical vapor deposition process we carefully remove the masking material from the substrate without damaging the Parylene layer. Once the mask is removed edges of the Parylene conformal coating around the areas where a masked area and a coated area meet can be observed. You can perform this either with bare eye with a lot of care under light (watch for the reflection) or using an optical microscope (magnification) for ease. Spotting the de-masking lines is a very assuring way of validating the presence of parylene. In the Figure below, a Parylene layer being peeled off of a wafer and on the right hand-side 10 μm features are shown [1]. With a careful eye you can spot the Parylene layer from the edges on a macroscale.

Parylene is a hydrophobic conformal coating meaning that if gets into contact with water the water will not spread but form semi-spheres on the Parylene surface. If your substrate or components will not be affected by water dropping a few drops of water on the areas where Parylene must be present would give a good idea of its presence. The dewetting angle of Parylene-AF4 is 100 degrees, Parylene C is ≈80 degrees and Parylene N is ≈75 degrees [2].

Other validation methods include electron microscopy and Fourier-transform infrared (FTIR) characterization by which you can obtain a high resolution image and a chemical fingerprint of the material, respectively.

REFERENCES

[1] S. Selvarasah et al., “A High Aspect Ratio, Flexible, Transparent and Low-Cost Parylene-C Shadow Mask Technology for Micropatterning Applications,” inTRANSDUCERS 2007 – 2007 International Solid-State Sensors, Actuators and Microsystems Conference, Jun. 2007, pp. 533–536, doi: 10.1109/SENSOR.2007.4300185.

[2] “(15) (PDF) Contact Angle of Parylene AF4 on a Sapphire Substrate,”ResearchGate. https://www.researchgate.net/publication/305905712_Contact_Angle_of_Parylene_AF4_on_a_Sapphire_Substrate (accessed Apr. 28, 2020).

该文章内容致力于散播新技术应用新闻资讯,很有可能有转截/引入之状况,若有侵权行为请联络删掉。

派旗纳米·官方网站

派旗纳米·官方网站