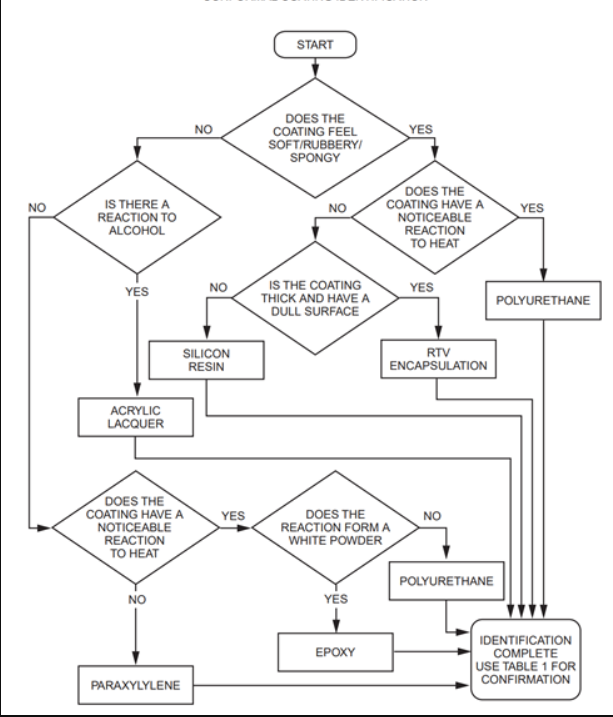

Conformal coatings provide a long-term, stable and reliable encapsulation method for the electronic components from the environmental effects. Different industries and service conditions calls for different protective coatings. In some cases, changes in the requirements or mistakes would call for action to remove the coating. While some coating materials are easily removed, some are virtually impossible to remove without damaging the products (eg. epoxy) . The coating removal process has been standardized by the standard IPC-7711C/7721C titled Rework, Modification and Repair of Electronic Assemblies [1]. According to the IPC-7711C/7721C coating removal starts by the identification of conformal coating (Chart. 1) type and followed by the selection of the method to be used depending on the substrate and components. If prepared onsite the coating material is generally known, but if the coating was done elsewhere the following chart can be used to identify the type of conformal coating.

Figure 1 IPC-7711C/7721C Conformal coating defining chart (Revision: B Date: 11/07) [1]

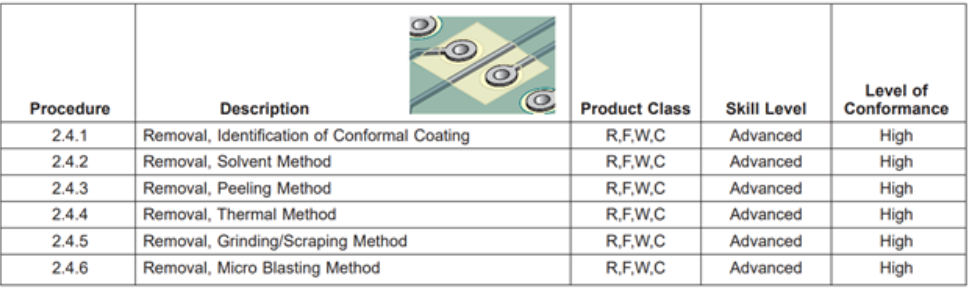

The method is selected in a way that the least or no damage is given to the substrate (be it PCB or silicon wafer etc.) and its components. Possible methods listed in the standard (Fig. 2) are listed below. Besides, oxygen plasma, laser ablation are methods that are highly preferred for conformal coating removal from microelectronics.

Figure 2 List of methods used in conformal coating removal IPC-7711C/7721C

Solvent Method: Removal of the conformal coating using a solvent is very attractive due to the bench-top type of process. Most conformal coatings are chemically very resistant and are very hard to remove by solvents. For small parts the solvent is applied using a using a foam swab. For larger parts the product can be immersed if the chemicals are not damaging the underlying electronic parts.

Peeling Method: Mechanically peeling off of the coating. This method might require pre-processing such as thermal, chemical processes. The peeling of can be done if the surface adhesion between the conformal coating and the bond surface is not strong. However, conformal coatings usually have very strong bonding interfaces with the substrates. While the method sounds attractive it is mostly not applicable.

Thermal Method: Thermal removal is done using the controlled heating. The sample is heated up in a controlled way and the coating can be tested for removal in a tiny spot. The test temperature elevated from room temperature to approximately at 100 °C and can be increased gradually if needed. The viscosity changes and component thermal budget must be watched out to protect the overall health of the electronics.

Grinding/Scraping: While this method sounds relatively easy it can be very invasive and extra attention is required. Friction between the abrasive and the surface or components may lead to device failure.

Micro Blasting Method: Abrasion operations can generate electrostatic charges however the chamber is grounded dissipating the static charges. Micro abrasive blasting propels explicit formulas of inert gas/dry air and abrasive media at the parylene-coated component, via a tiny nozzle attached to a stylus; either a handheld human or automated systems can be used to pinpoint the targeted removal area.

Table 1 Conformal coating materials and removal method according to IPC-7711C/7721C.

|

Conformal |

Removal Method |

Material Properties |

||||||||

|

Solvent |

Peeling |

Thermal |

Grinding/ |

Micro |

Hardness |

Surface Adhesion |

Precursor |

Ease of removal |

||

|

Parylene |

THF 3-4 hrs |

PREFERED |

YES |

YES |

hard |

Very strong |

Powder |

Very Hard |

||

|

Epoxy |

Methylene Chloride NOT compatible with PCBs and electronics Cancer risk |

PREFERED Heat above epoxy softening point (Tg). Damages most electronics. |

YES |

YES |

hard |

Very strong |

Liquid |

Very Hard |

||

|

Polyurethane |

PREFERRED |

PREFERED |

YES |

YES |

hard/med/soft |

Medium |

Liquid |

Hard |

||

|

Acrylic |

PREFERED (alcohol) |

YES |

YES |

YES |

hard/medium |

Strong |

Liquid |

Easy |

||

|

Silicone |

PREFERED (thin ˂0.064 cm ˂0.025 in |

PREFERED (thick) >0.064 cm >0.025 in |

YES |

YES |

soft |

Low to strong |

Liquid |

Moderate |

||

Acrylic is very easy to handle and readily solvable in common solvents such as xylene. If the coating must be removed or reworked after the application, acrylic is the best choice for the application.

Polyurethane, parylene, epoxy and silicone are chemically inert and their chemical removal is not very easy or may require chemicals that can also damage the PCB and underlying substrate. Chemical removal of epoxy and polyurethane is done by harsh chemicals which is not a healthy option. Mostly thermal coating removal is advised for epoxy. Thermal coating removal technique is not always advisable as it can leave stains, discoloration and damage the electronic components.

Parylene is a pinhole free, uniform conformal coating that can coat the smallest crevices of the electronic products and it can be hardly removed by chemicals. Tetrahydrofuran (THF),a very harsh chemical, can aid in the delamination of the parylene layer which can later be removed by tweezers. Approximately 3 hours of immersion is needed for delamination. Benzolyl benzoate and chloronapthelene above 150 °Cs are also known to remove parylene however they can damage the PCB and electronic components therefore are not advised. Chemical removal of parylene is not a recommended process.

Laser ablation, reactive ion etching (oxygen plasma), and micro-abrasion are the best options for the removal of parylene. These methods can be applied precisely for microelectronic structures on silicon wafers as well. Also, micro abrasion blasting using abrasives and compressed air can remove conformal coatings such as parylene and epoxy abrasives.

Mechanical manipulation of the coatings must be applied carefully since they can cause unexpected failures due to mechanical impact on the structures.

该文章内容致力于散播新技术应用新闻资讯,很有可能有转截/引入之状况,若有侵权行为请联络删掉。

上一篇: 防水防腐之腐蚀机理

下一篇: AATCC79-2010纺织品吸水性

派旗纳米·官方网站

派旗纳米·官方网站