“ 星战:第四集 – 新的希望”中的高朝完毕 战 是电影界上最令人激动和激动人心的情景之一。Luke Skywalker和theRebels对帝国舰队开展了崩溃的进攻。无法催毁Empire恐怖的死星将对该星球导致破坏性不良影响。安全驾驶他的TIE战机,邪惡的Darth Vader正在调查LukeSkywalker的X翼并将其锁住在总体目标上。就在来看allhope不成功的情况下,赎罪的Han Solo和他忠实的Wookie伙伴Chewbacca出现意外地在万佳猎鹰的最后一刻抵达,便于从Vader中大大的地阻拦卢克。卢克信赖军队,在作战站的热出气口发送反质子鱼雷艇,造成可燃性的链式反应和死星的摧毁。

tubeembed

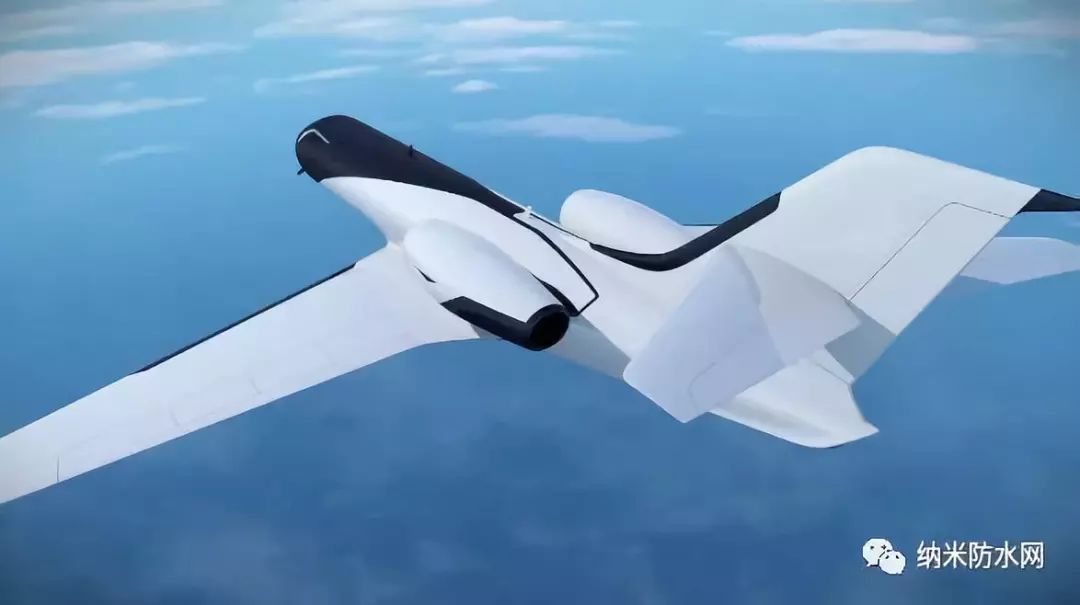

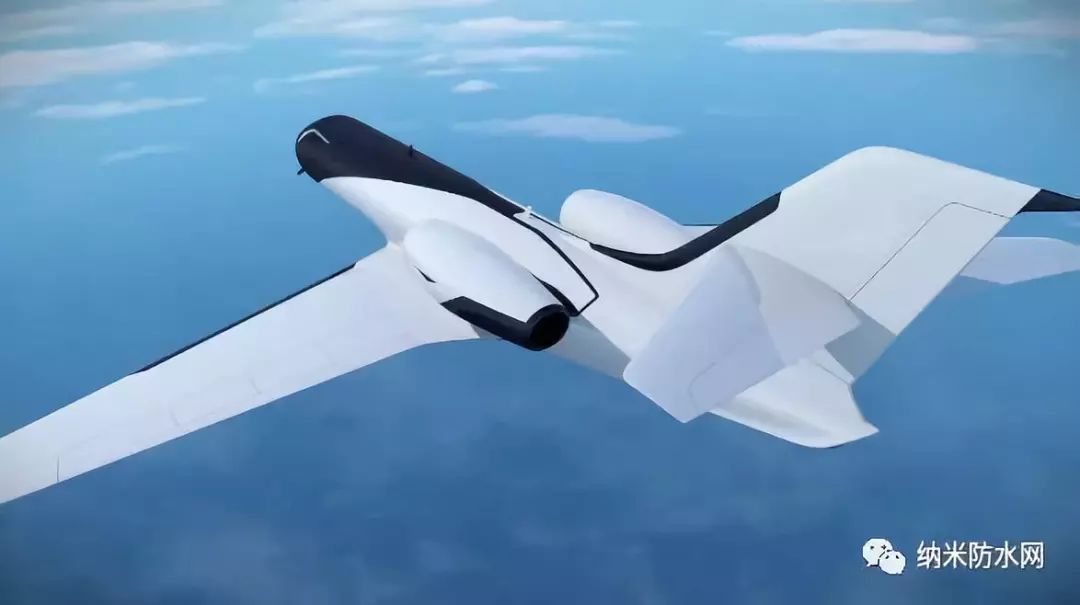

遭受多翼X翼星际战斗机的鼓励,而且因为她们坚信每日任务的必要性,叛逆同盟根据完成战胜邪恶帝国的总体目标找到新的期待。与叛逆同盟一样,航天航空也必须航空员实际操作,便于安全性地达到目标。优秀的电子产品和有使用价值的元件用以航行管理方法,当代飞机场和战机,用以航行管理方法,操纵,仪表盘,导航栏,通讯,感应器和发电量,务必靠谱地实行。这种优秀的电子材料必须非凡的特性,在其中净重,稳定性,信号完整性,损耗和承担明显自然环境的工作能力对电路原理尤为重要。伴随着航天航空工业生产特性标准的进一步提高,

航天航空的优选维护

镀层很多年来,喷漆,浸涂和涂漆的液体保形建筑涂料为航天航空电子设备给予了一定的程度的维护。可是,他们没办法给予优秀技术创新需要的维护等级。比如,传统式镀层有可能在镀层中或下边捕获汽泡。假如这种汽泡在高原地区自然环境中或在空间实际操作期内开启,则有可能造成曝露的电源电路产生常见故障。 Parylene 通过真空泵堆积全过程,因而未找到捕获汽泡的概率。Parylene是一种全透明的塑料薄膜保形建筑涂料,可以在涂成它的电子产品上增多一层。

Parylene保形建筑涂料 在现如今的电子设备中激发着非常重要的功效,它具备优异的间隙和双层透水性,无以伦比的隔绝特性,低透水性汽体和体内湿气,抗紫外光性和很高的耐热性。航天航空电子产品也常常承担持续震动和偏激溫度,尤其是地球上的绝缘层自然环境。这种严苛的状况会危害无防护的电子产品,造成内容丢失,没法接受航行期内需要的重要信息。根据makingsure采用了适度的防范措施,可以大大的缓解飞机场从风险电流量和常见故障情况的危害。聚对二甲苯可以承担航天航空运用中碰到的偏激溫度和温度标准。

航天航空ParyleneCoating

Parylene镀层早已在全部航天航空制造业中用以电子线路的全部行业,包含在区域的偏激情况下曝露于体内湿气,冷疑,有机化学腐蚀,有机溶剂,零下温度或紫外光的这些。Parylene保形镀层符合规定,并明显增加了有價值的构件的安全性使用寿命,比如工业生产级感应器,飞机场照明灯具中的LED,走线和走线部件,COTS,辐射源探测仪这些。

假如存有可能会导致无效的時间不正确作用,则非常高的使用价值和人的生命很有可能会遗失。因而,关键的是尽一切勤奋以最好是地维护核心部件。用以航天航空运用的PCA(印刷电路板部件)务必维持严苛的标准并承担恶劣的环境标准。这种部件通过一系列检测,包含高/超低温,空气和溫度冲击性,耐酸类和防水性,环境湿度和易燃性。

结果

为了防止毁灭性不良影响,Parylene镀层愈来愈多的用以提升自主创新和繁杂技术性的稳定性.Parylene早已变成繁杂的航空公司运用的优选维护镀层,因为它可以在特殊条件下,在特殊阶段内给予靠谱的维护。時间,沒有不成功。

星战 虏获了很多世世代代的内心和观念,因为它具备诗史一样的情节,其震惊的动画特效及其扣人心弦的歌曲。除此之外,它产生了开朗,想像力,或许最重要的是期待。性类似 星战,聚对二甲苯镀层给予创造性解决困难foraccelerated和飞速发展的技术性。假如你依然不敢相信Paryleneis是高质量的保形镀层,Darth Vader很有可能要说,“我发现了你的欠缺令人深思的事儿。”

Para-Coat技术性企业根据 制订优良的业务发展战略并坚信Parylene 镀层加工工艺的必要性而备受鼓励, 并根据十几年的服务项目维持了高质量的信赖,以符合全部规定的功能规范。根据设置Parylene堆积高效率的规范,大家给予顾客启迪的解决方法,并 期待您将运用大家的专业技能。

The climactic end battlein Star Wars: Episode IV – A New Hope is one of the mostsuspenseful and thrilling scenes in cinema history. Luke Skywalker and theRebels launch a desperate attack on the Imperial fleet. Failure to destroy theEmpire’s dreaded Death Star will have devastating consequences to the galaxy.Piloting his TIE fighter, the evil Darth Vader is zeroing in on LukeSkywalker’s X-wing and has it locked in on target. Just when it seems that allhope is lost, the redeeming Han Solo and his loyal Wookie companion, Chewbacca,unexpectedly arrive at the last moment in the Millennium Falcon to dramaticallysave Luke from Vader. Luke with trust in the Force, fires proton torpedoes atthe thermal exhaust port of the battle station leading to an explosive chainreaction and the destruction of the Death Star.

tubeembed

Encouraged by theversatile X-wing Starfighter and because of their belief in the importance ofthe mission, the Rebel Alliance found renewed hope by accomplishing their goalin defeating the evil Empire. Like the Rebel Alliance, aerospace also hasaircraft operating that require more than a pilot in order to safely completeeach mission. Advanced electronics and valuable components are used inspacecraft, modern aircraft, and fighter jets for flight management, control,instrumentation, navigation, communication, sensors, and power generation thatmust perform reliably. These advanced electronic materials require superiorperformance where weight, reliability, signal integrity, attenuation, andability to withstand intense environments are critical to the circuit design.As demands for performance in the aerospace industry continue to increase, it’scrucial to provide adequate protection to enhance the reliability of theircomplex technologies.

The Protective Coatingof Choice for Aerospace

For a number of years, liquid conformal coatings that are sprayed, dipped, andbrush applied offered a level of protection for aerospace electronics. However,they simply do not offer the level of protection that is required in advancedinnovative technologies. For instance, traditional coatings have the potentialto trap air bubbles in or underneath the coating. If these air bubbles were toopen in an environment at high altitudes or during space operations, it canpotentially cause the exposed circuit to fail. Parylene goes through avacuum deposition process, so there is no potential for the trapping of airbubbles. Parylene is a transparent, thin film conformal coating that adds noweight to the electronic device on which it is coated.

Parylene conformal coatings playa critical role in today’s electronics by offering excellent crevice andmulti-layer penetration, unrivaled barrier properties with low permeability togases and moisture, and UV resistance and extreme high thermal stability.Aerospace electronics are also routinely subjected to continuous vibration andextreme temperatures especially above the insulating atmosphere of the earth.These demanding situations can impair unprotected electronics and cause a lossof data and failure to receive vital information necessary during flight. By makingsure the proper precautions have been taken, damage to an aircraft fromhazardous currents and faulty conditions can be greatly mitigated. Parylene isable to withstand the extreme temperature and pressure conditions encounteredin aerospace applications.

Aerospace ParyleneCoating

Parylene coatings have been used throughout the aerospace industry in all areasof electronic circuitry including those exposed to moisture, condensation,chemical attack, solvents, sub-zero temperatures, or UV-rays in the extremeconditions of space. Parylene conformal coating meets the requirements andprolongs the safety lifetime significantly for valuable components such as,industrial grade sensors, LEDs in aircraft lighting, wiring and cablingassemblies, COTS, radiation detectors, and much more.

Extremely high valuesand human lives are at the risk of being lost if there are ill-timedmalfunctions causing systems to fail. Therefore, it is important to make everyeffort for the best possible protection of the vital components. PCAs (PrintedCircuit Assembly) for aerospace applications must maintain strictspecifications and withstand aggressive environmental conditions. Theseassembles undergo a series of tests including high/low temperature, atmosphericand temperature shock, chemical and moisture resistance, humidity, andflammability.

Conclusion

In order to avoid devastating consequences, Parylene coatings are increasinglybeing used to enhance the reliability of innovative and complex technologies.Parylene has become the protective coating of choice for sophisticatedaerospace applications because of its ability to provide reliable protectionunder specific conditions, for a specified period of time, without failure.

Star Wars capturedthe hearts and minds of many generations because of its epic storytelling, itsvisually stunning special effects, and its spellbinding music. In addition, itinspired optimism, creativity, and perhaps most importantly, hope. Similarto Star Wars, Parylene coating offers creative problem solving foraccelerated and evolving technology. If you still don’t believe that Paryleneis the superior conformal coating, Darth Vader might say, “I find your lack offaith disturbing.”

Encouraged by having agood business strategy and a belief in the importance of the Parylene coatingprocess, Para-Coat Technologies establishedand has maintained a high level of trust with years of service through acommitment to meet every required performance standard. By setting the standardfor Parylene deposition efficiency, we offer customer-inspired solutionsand hopeyou will take advantage of our expertise.

大量纳米防水新闻资讯请关心“派旗纳米”微信公众号

该文章内容提高散播新技术应用新闻资讯,很有可能有转截/引入之状况,若有侵权行为请联络删掉。

派旗纳米·官方网站

派旗纳米·官方网站